Ford has leveraged quantum computing technology to address one of its most complex production challenges, achieving remarkable results in just five minutes. Collaborating with D-Wave Quantum Inc., Ford Otosan—the automaker’s joint venture in Turkey—deployed a hybrid-quantum application to optimize production sequencing for its Ford Transit line, demonstrating the transformative potential of quantum computing in automotive manufacturing.

Ford Transit vehicles are among the most customizable commercial vehicles globally, with over 1,500 variants in production. This variability creates significant challenges for manufacturing efficiency, as producing identical products consecutively is far more productive than frequently adjusting for custom specifications. The sequencing process involves adhering to constraints across the body shop, paint shop, and assembly line while maximizing throughput—a task that classical computing methods struggle to solve efficiently.

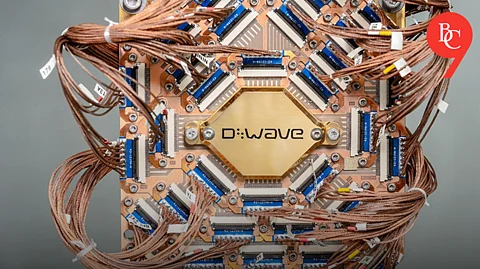

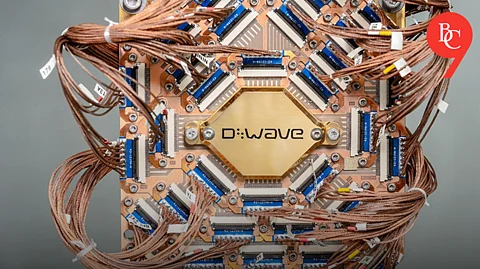

Using D-Wave’s annealing quantum computing technology through the Leap™ quantum cloud service, Ford Otosan addressed these challenges by optimising production sequencing. The scheduling time for 1,000 vehicles per run dropped from 30 minutes to less than five, showcasing quantum computing’s ability to solve highly constrained optimization problems rapidly. The hybrid-quantum approach allowed Ford Otosan to adapt quickly to changes in demand or auto part availability without disrupting productivity. By reducing workload imbalances and minimising unplanned maintenance, Ford Otosan increased peak production throughput of vehicles per hour, reclaiming lost manufacturing time and achieving efficiencies not possible with classical computing alone.

Quantum computers operate on principles of quantum mechanics, enabling them to process information in ways that classical computers cannot. Unlike binary systems limited to zeros and ones, quantum systems can encode information in multiple states simultaneously, allowing them to tackle complex problems involving numerous variables and constraints.

For Ford Otosan, this meant solving a highly constrained optimization problem,balancing throughput while adhering to physical and workforce constraints,at unprecedented speeds.

Ford’s success with D-Wave highlights the growing role of quantum computing in solving real-world industrial problems. As Dr. Alan Baratz, CEO of D-Wave, stated: “For manufacturers on the leading edge of innovation such as Ford Otosan—D-Wave’s quantum computing technology has proven capable of finding better solutions to complex problems than classical computing alone.”

Ford Otosan aims to activate quantum scheduling across additional body shops and expand optimization benefits to other areas of its operations. This breakthrough sets the stage for broader adoption of quantum solutions across industries where complexity and efficiency are paramount.